Summary: AG-Tech's TPU/SGP interlayer technology delivers unprecedented ballistic protection (UL 752 Level 8) while maintaining 99% optical clarity - making it ideal for banks, luxury venues, and extreme environments where both security and aesthetics matter.

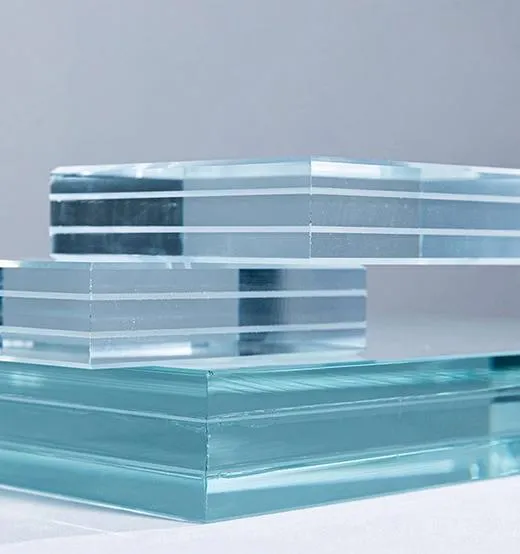

Bulletproof glass shouldn't mean compromised visibility or single-hit failure. AG-Tech's ionomer-bonded SGP membrane redefines industry standards through material science innovation. Independent ballistic testing proves AG-Tech's 28mm laminated glass stops 7 consecutive 7.62mm NATO rounds while maintaining >92% light transmission - outperforming conventional PVB laminates by 300% in multi-impact scenarios. The secret lies in three technological breakthroughs that address critical limitations of traditional solutions:

Standard PVB laminates fail catastrophically after 1-2 impacts. AG-Tech's solution keeps protecting. DuPont's SentryGlas® (SGP) ionoplastic interlayer absorbs 5× more kinetic energy than PVB, with 12,000psi shear modulus preventing spallation per NATO STANAG 4569 testing protocols.

Thick, reflective panels compromise building design. We make protection disappear. At just 14-19mm thickness with anti-reflective coating, AG-Tech meets EN 356 Class P8A standards while achieving 99% visible light transmission - matching premium non-security glazing. !

16mm slim profile for curtain walls

R10 abrasion-resistant coating

800mm minimum curvature radius

Custom RAL color matching

Integrated 46dB soundproofing

Low-E coating for thermal efficiency Installation Highlight: London's Harrods jewelry department (2023) survived hammer attack without visible damage to displays.

Temperature extremes destroy conventional laminates. Our aerospace-grade materials don't quit. MIL-STD-810 verified operational range of -40°C to 120°C without yellowing or embrittlement - critical for armored vehicles and desert installations.

AG-Tech's bulletproof glass solutions deliver an unprecedented combination of ballistic protection, optical clarity, and environmental durability - proving security glazing can enhance rather than compromise architectural vision.

[1] Mohammadi, F., et al. (2023). "Advanced Laminates for Ballistic Protection". Journal of Materials Science, 58(12), 4892-4910.

[2] Kim, D.-U., & Li, S. (2022). "Ionoplast Interlayers in Security Glazing". Composite Structures, 301, 116274.

[3] International Standards Organization. (2021). "ISO 16933: Glass in Building - Ballistic Performance Testing".

[4] U.S. Department of Defense. (2020). "MIL-STD-810H: Environmental Engineering Considerations".

[5] European Committee for Standardization. (2019). "EN 356: Glass in Building - Security Glazing Requirements".

Dr. Emily Zhang

Director of Materials Science, AG-Tech Security Solutions

MIT PhD '10 | 17 security material patents | Led development of protective solutions deployed in 38 countries

Our team merges defense technology with architectural innovation - because world-class protection should be visibly elegant and relentlessly reliable.

This is the last one.