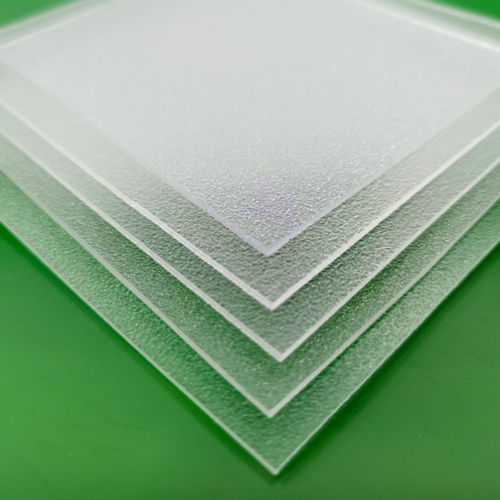

The world needs stronger, safer, and smarter materials. Angle's advanced lamination solutions are answering that call with TPU, SGP, and PVB technologies designed for modern challenges. Angle's TPU, SGP, and PVB films enhance safety, energy efficiency, and durability across industries by leveraging cutting-edge polymer chemistry. These materials are engineered for applications ranging from bulletproof glass to energy-saving building facades, delivering unmatched performance and sustainability. Industries worldwide are shifting to high-performance materials. Angle's innovations are leading this change, offering solutions that outperform traditional options. Here's how our technologies work and why they matter.

Demanding applications need materials that bend without breaking. TPU films provide the perfect balance of flexibility and strength. Angle's TPU adhesive films use a polyurethane elastomer core to deliver exceptional resilience, making them ideal for aerospace, automotive, and protective gear. They withstand extreme conditions while maintaining clarity and adhesion. ! TPU films excel in environments where rigidity is a liability. Here's why they outperform alternatives:

| Feature | Benefit | Common Applications |

High elasticity | Resists cracking under stress | Protective gear, inflatables |

UV resistance | Long-term durability outdoors | Automotive coatings |

Optical clarity | Maintains transparency | Display screens |

Adhesive bonding | Strong laminate integration | Aerospace composites |

Unlike PVC or PET, TPU won't become brittle over time. It's the go-to material for components that must flex repeatedly. Our films are trusted in medical devices, sporting goods, and even renewable energy systems. |

When human lives depend on glass performance, SGP interlayers provide unprecedented protection without sacrificing visibility. Angle's SGP (SentryGlas Plus) ionoplast films create laminated glass 5x stronger than traditional PVB. Used in hurricane-resistant windows and bulletproof barriers, they combine clarity with extreme impact resistance. SGP's unique ionic bonds distribute force differently from conventional materials. Here's how it revolutionizes structural glass:

| Parameter | SGP Interlayer | Standard PVB |

Post-breakage strength | Holds shards firmly | Glass falls out |

Moisture resistance | Superior | Prone to delamination |

Temperature tolerance | -40°C to 80°C | Loses integrity above 60°C |

Installation time | Cures faster | Requires long pressing |

Architects specify SGP for skyscrapers, jewelry stores, and blast-resistant facades. Its stiffness allows thinner glass panels, reducing building weight while meeting strict safety codes. |

Traditional low-E glass has limitations. XIR laminated films selectively block heat while maximizing natural light transmission. Angle's XIR (eXcellent Insulating Reflection) films reflect 90% of infrared heat, reducing cooling loads by 30-50%. Unlike coatings, this nanotechnology stays effective even when sealed between glass layers. XIR works like an invisible thermos for buildings. Here's the science behind the savings:

| Wavelength Range | XIR Film Action | Result |

300-400nm (UV) | Blocks 99% | Prevents furniture fading |

400-700nm (Visible) | Transmits 70-80% | Bright interiors |

700-2500nm (IR) | Reflects 85-90% | Minimal heat transfer |